From practice and service repairs it is known that 90% of accidents and problems with the drone are caused by the pilot and his improper handling of the drone, but there are also situations where the drone is at fault, or a fault that was not discovered during manufacture. In these situations, as an authorized service, we guarantee a repair under warranty (up to 2 years).

A step that will make this process easier and faster is the need to export post-accident data (logs)

Important notes

Immediately saving the data after encountering a problem will ensure the accuracy of the data transfer and avoid overwriting the data after switching the RC (controller) on/off several times, part of this step it is necessary to have the RC connected to the internet to synchronize the data during and after each flight.

Due to storage space limitations, the data storage in the drone and the controller is different: the drone can store 25 logs while the controller can only store 10 logs.

This is why it is best to deal with the situation immediately after a problem arises and not to manipulate the drone further.

Preparation before uploading data

(These steps must be done in any case)

- Check the firmware version of the drone (if it is only a problem with the driver, this step can be skipped)

- Check the firmware version of the driver

- Description of the accident, error that occurred: at what time, during what conditions, during what operation, what error or problem occurred

- The time of the accident, it is necessary to know at least the approximate time when the problem occurred in order to send and check the correct data

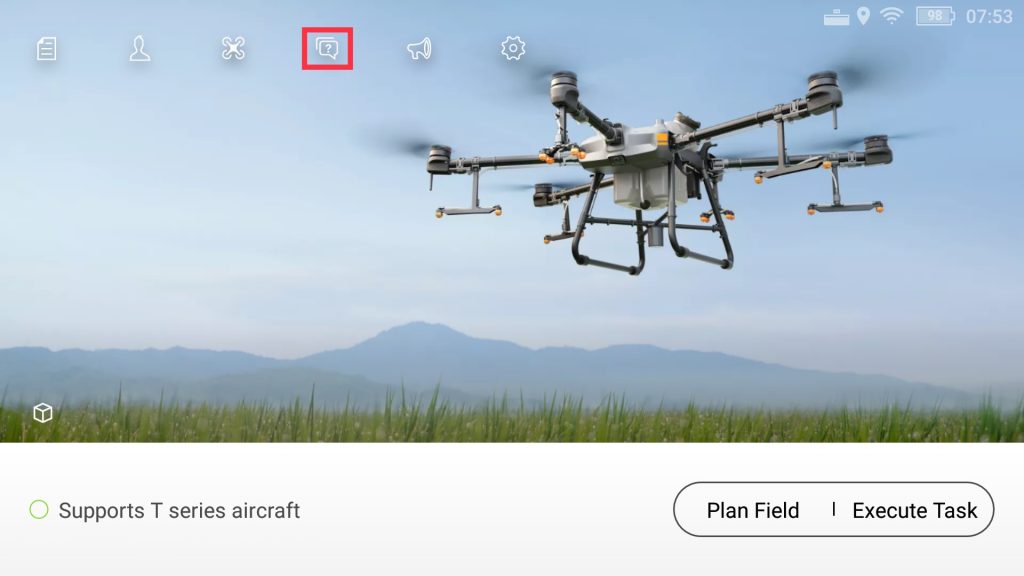

How to export data

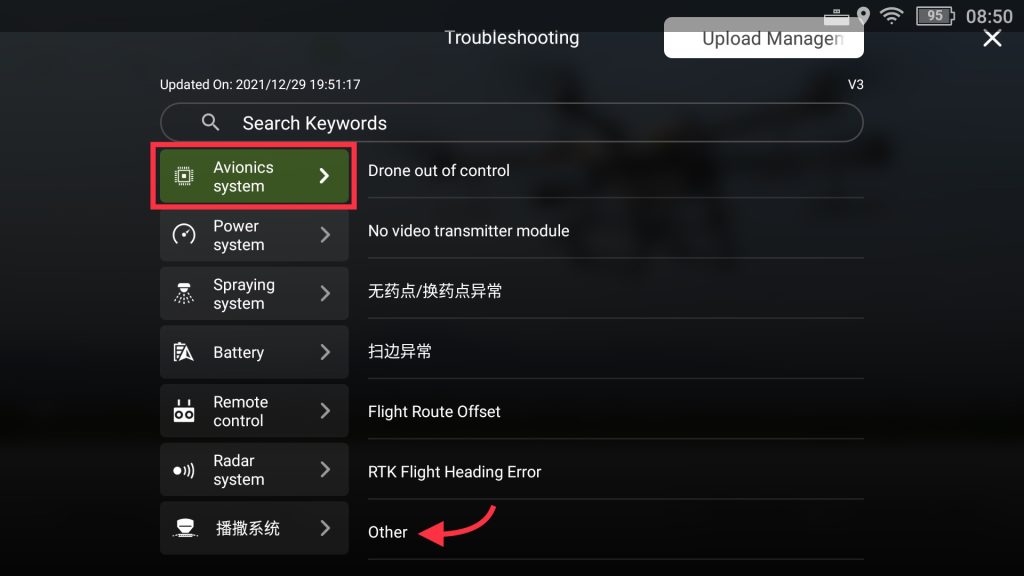

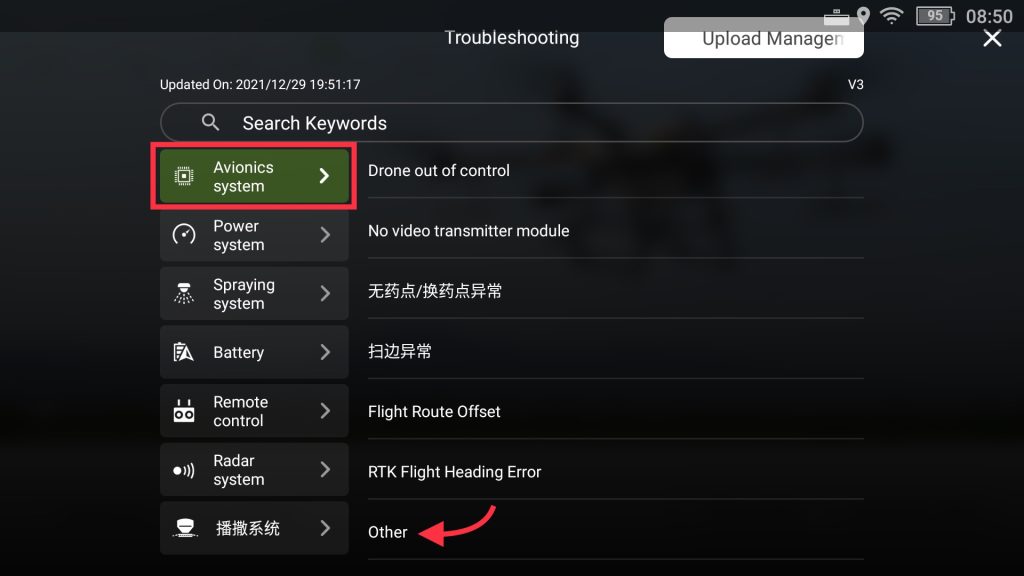

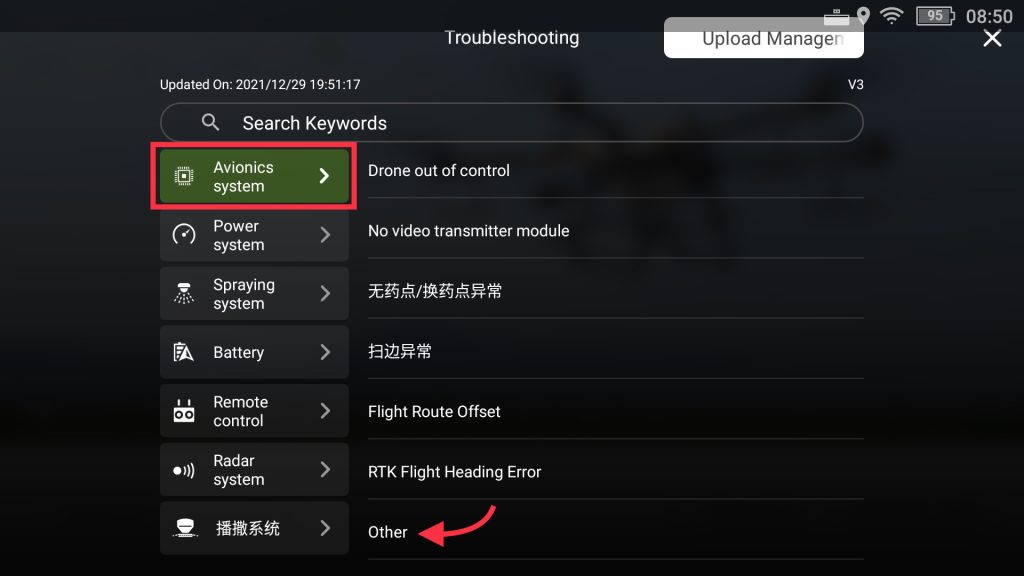

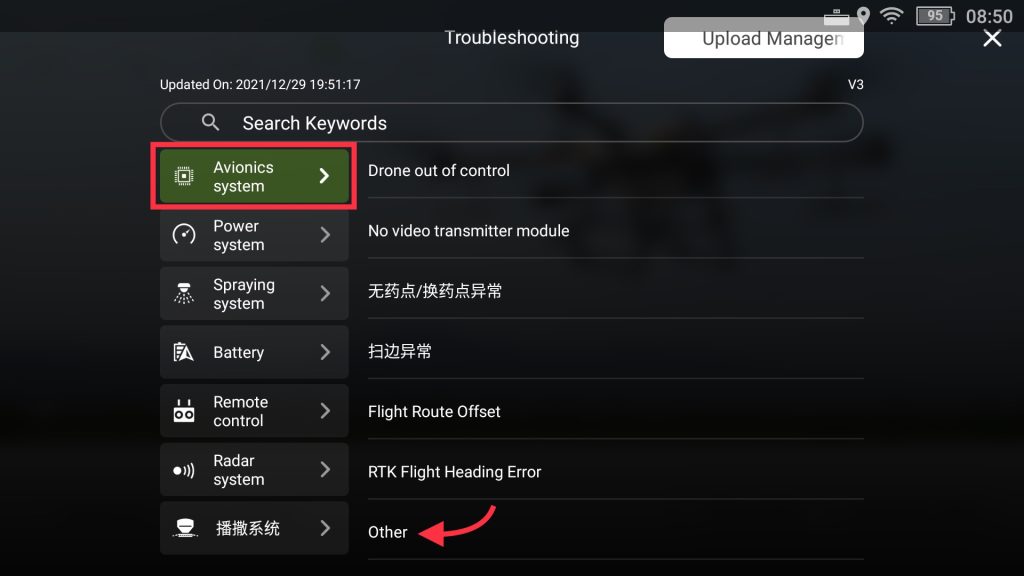

1. In the event of an aircraft accident, flight abnormalities, spraying and scattering abnormalities

- It is necessary to provide data from “Avionics System” -> Other

2. In case of abnormal radar functionality

- It is necessary to provide data from “Avionics System” -> Other & Radar System -> Other

- Photos of the surroundings where the error occurred, e.g. trees that the drone was unable to avoid, obstacles or power lines

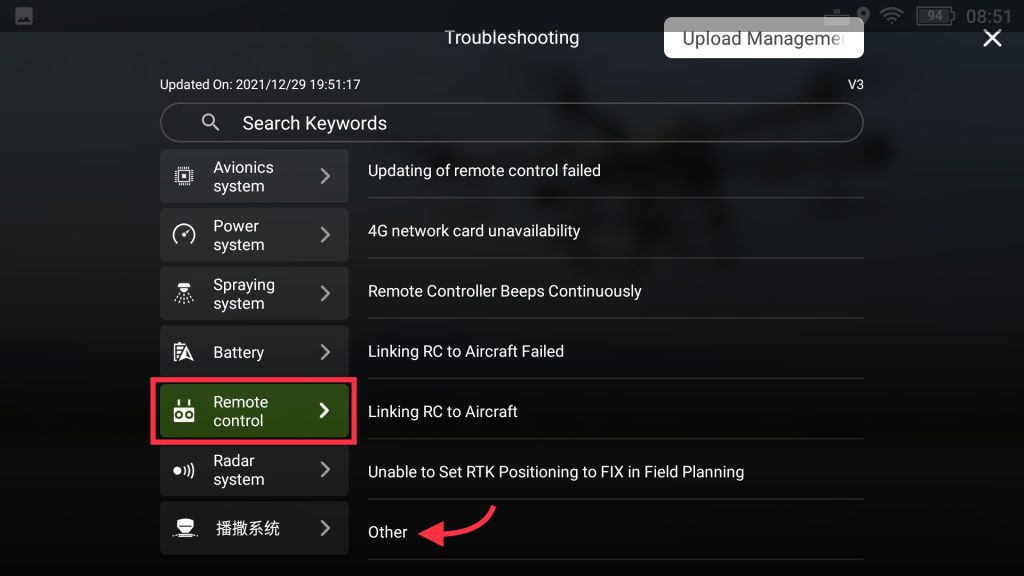

3. In case of RC (controller) abnormalities such as black screen display, joystick error and system crash

- Video recording of the error

- It is necessary to provide data from “Remote Control” -> Other

4. In case of abnormal transmission and image control such as connection loss, screen freeze

- It is necessary to provide data from “Avionics System” -> Other & Remote Control -> Other

- Video recording of the error

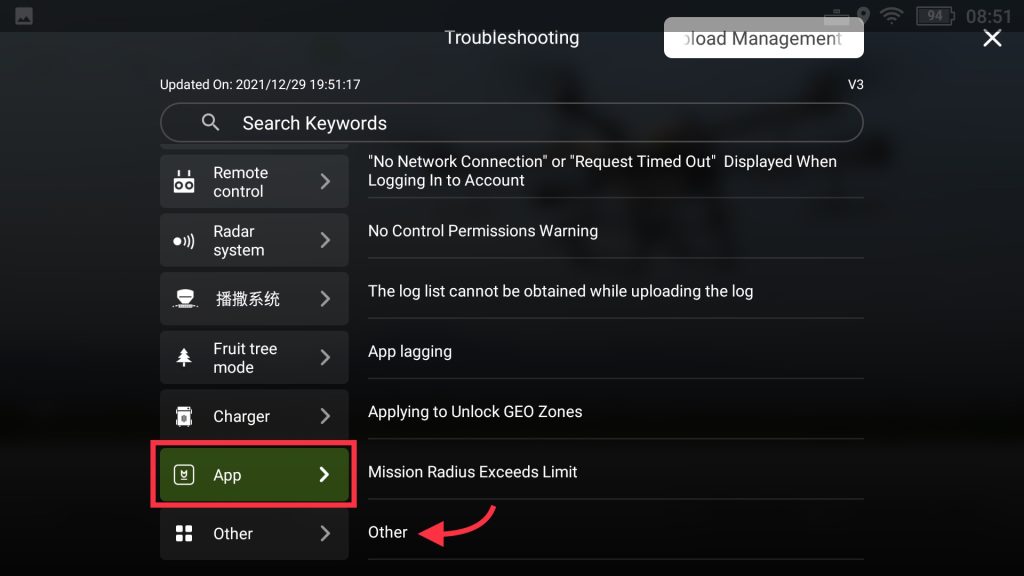

5. In case of abnormal APP functionality

- Video recording of the error

- It is necessary to provide data from “APP” -> Other

6. In case of firmware update failure

- Video recording of the error

- It is necessary to provide data from “Avionics System” -> Other

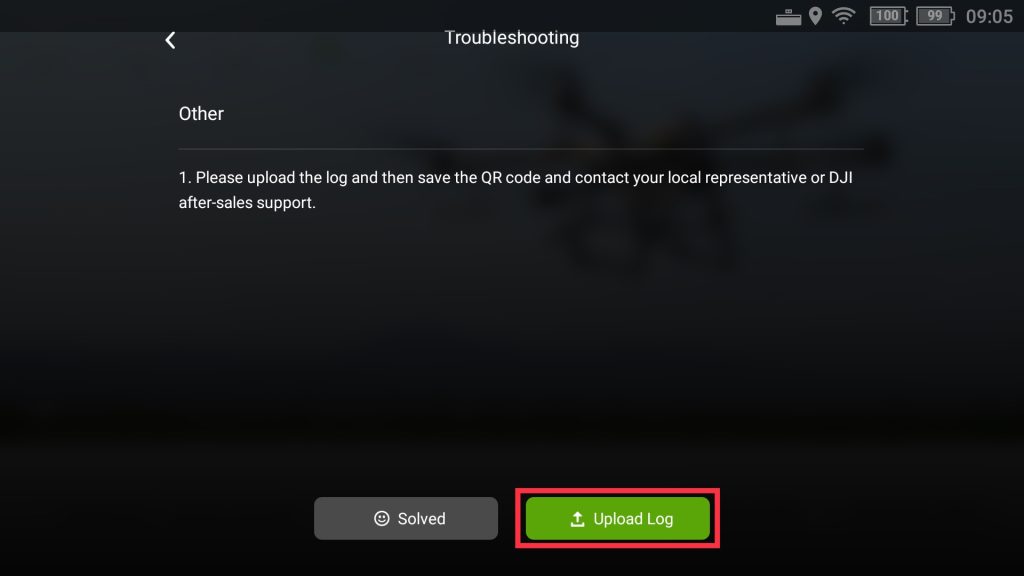

- After selecting the correct error category, you need to upload the logs

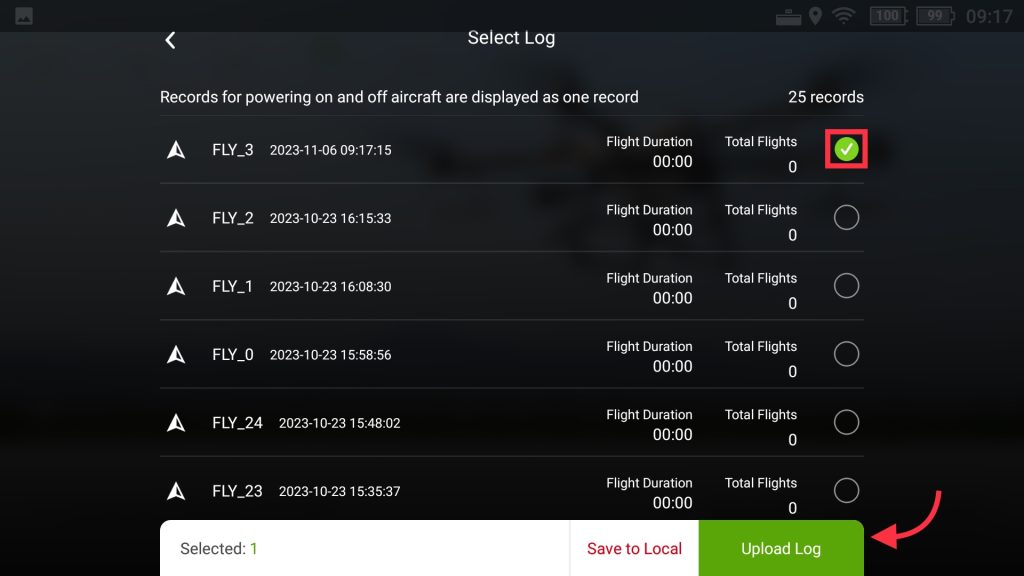

- Clicking on “Upload logs” will display a list of saved logs from recent flights and drone handling

- It is necessary to select the correct log (according to the time when the error occurred) and upload it

- After the data is processed, you will see a QR code, you need to record it with a screenshot and then send it to an authorized service center

After receiving the data from the client, the authorized service investigates the event and then evaluates it as:

- Pilot error, which is not covered by the warranty period (if the equipment is still under warranty) and the service will be performed at the client’s expense

- Defective equipment covered by the warranty (if the equipment is still under warranty) and service will be performed at DJI’s expense

In order to clarify the rules of spray drift by agricultural drones (or drones) under different influencing factors, also to guide agricultural drones to safely and efficiently carry out crop protection operations and to ensure safety for non-target organisms and the environment, a spray drift test was carried out with a DJI Agras T30 drone.

The test was conducted at the test site of the Chinese Academy of Agricultural Sciences. A DJI Agras T30 agricultural drone was used for testing. The terrain on which the test was conducted was flat and the surrounding area was open, free of obstacles. The flight speed of the T30 drone was selected as 3 m/s, 4 m/s, 5 m/s and 6 m/s. The flight height can be selected as 2 m, 3 m and 4 m. It is also possible to choose between normal and coarse drop size. Each combination of parameters was used to measure the droplet deposition and spray drift of an agricultural multi-rotor drone at three different crosswind speeds. The test was carried out on an area of 128 m x 125 m (length x width). Six sampling strips were arranged in the sampling area with an interval of 5 m between each sampling strip. The first and last sampling strip were 50 m from the edge of the test area. The sampling area includes 0-20 m in the operational area and 0-50 m in the downwind drift area.

After application, wait 5-10 minutes, then check that all droplets on the filter paper are dry, put them in order in zip-lock bags and store the samples in a dark and cool place. Later, the samples are processed and measured. The agricultural drone is set to auto operation mode with multiple applications, and the flight path of the drone is 125m long to ensure that the agricultural drone in the sampling area will fly at a constant speed. An aqueous solution of Rhodamine B at a concentration of 5 g/l was prepared prior to the test. Subsequently, the drone was filled to 50% capacity, so up to 15 l. Before the test it is of course necessary to check the functional condition of the drone nozzles and the flow calibration. After the wind direction meets the requirements and stabilizes, the drone will take off with the auto-flight button, apply RTK, and return to the takeoff location from the upwind direction after spraying.

Analysis and conclusion of testing

- Effect of crosswind velocity on drop drift:

Crosswind speed is the most important factor affecting the drift distance and the amount of drifted droplets, and the best operating condition is when the crosswind speed is less than 3.4 m/s.

- Effect of flight height on droplet drift:

When the crosswind speed is in the range of 0-3.4 m/s and the flight height is 2 m, 3 m and 4 m, the amount of settled spray droplets in the operating area gradually decreases, the uniformity of droplet distribution deteriorates, and the droplet drift distance gradually increases. When the crosswind speed is greater than 3.4 m/s, the change of working height has almost no effect on the droplet deposition and drift, and the main influencing factor is the crosswind speed.

- Effect of ambient temperature and humidity on drift:

The effect of humidity on droplet drift is more significant provided the ambient temperature is 15-30 °C, the crosswind speed is less than 3.4 m/s and the humidity is in the range 20-80 %. As the ambient humidity increases, both the amount of drift and the drift distance decrease.

The optimum ambient humidity range to reduce fog drift is: ambient humidity above 60%. When the ambient wind speed reaches more than 3.4 m/s, the change in ambient temperature and humidity has no significant effect on droplet drift.

In Switzerland, a “National Standard Scenario” has been developed for unmanned aerial vehicles (or drones) for spraying. This “scenario” contains a number of important points that must of course be fulfilled in order for drones to be used for the application.

- The type of drone must be approved by Agroscope for “ground application” and each drone must pass sprayer testing through the Agroscope company

- A company operating a drone must have a “Specific Operations Risk Assessment” (SORA) approved by the Federal Civil Aviation Authority.

After 2025: Spraying drones will need a permit from the Federal Civil Aviation Authority under SORA or EU-PDRA under (EU) 2019/947. According to current information, around 100 drones are currently being used for spraying in Switzerland.

The approval and testing process that each type of drone has to go through with the Agroscope organisation is a set of many activities carried out with these drones. (The DJI Agras T30 drone, for example, has passed this testing and is authorized to work) To begin with, the test criteria for the homologation of these drones are set, namely:

- The sprinkler system shall comply with the principles of ISO 16122

- For lateral distribution of spray liquid, the coefficient of variation must be

- Accuracy of automatic flight paths +/- 50cm

Standard controls for the spray system (ISO 16122)

One of the main parts of Agroscope’s testing is a standard check of the technology and the spray system. This consists of several points such as:

- Available filters

- Nozzle dripping after stopping spraying

- Nozzle flow

- Indication of flow rates or pressure

- Leaks

- Weight…

Spray liquid transverse distribution

This is being examined on a 6m x 3m “Sampler” (see Figure 3). The principle is to control the precise dosing from all nozzles (see Figure 4) while hovering continuously above the ‘Sampler’ at a height of 2.5 m

Influence of flight height on distribution

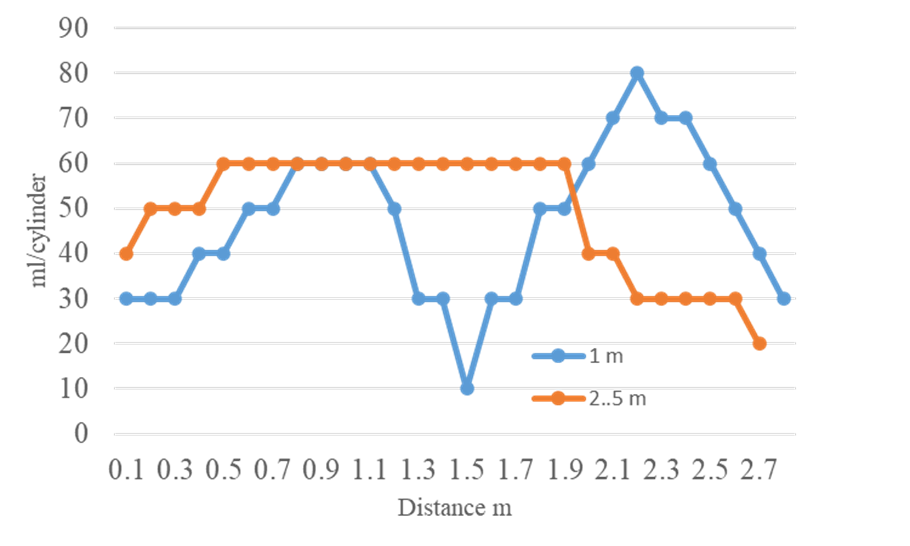

Transverse distribution at 1 to 2.5 m flight height (see Graph 1)

At heights of 1m and below, no suitable distribution occurs 2.5 – 3m provides much better distribution (less influence of individual propellers and more homogeneous airflow)

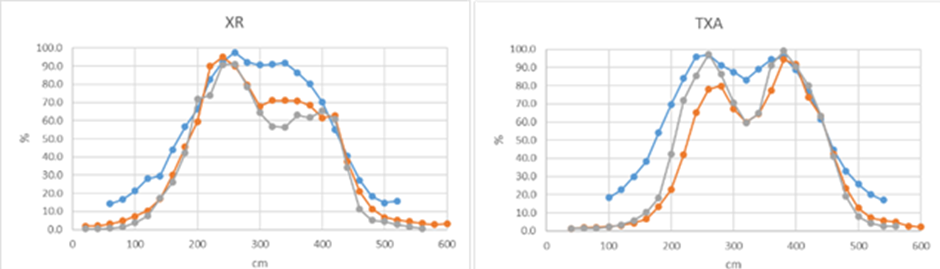

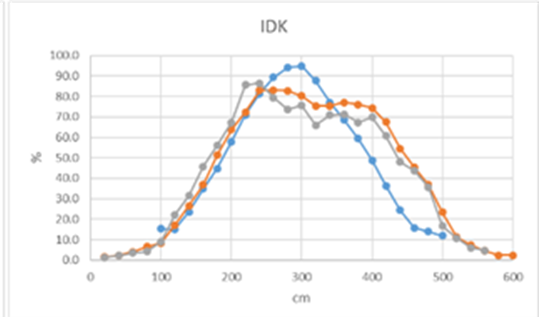

Transverse distribution with different nozzle types and different measurement methods

In this testing, 3 measurement methods were used:

- Patternator

- Tracer and photometric analysis

- Water-sensitive paper

And 3 types of nozzles:

- Teejet XR

- Teejet TXA

- Lechler IDK

Testing showed that there were no significant differences between the methods (see Figure 2)

Flight path accuracy

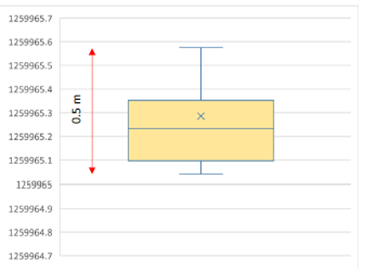

In this testing, the drone flies according to predefined routes (simulating a field, 3 bands) and has an additional RTK-GNSS data logger attached to it (see Figure 5) to measure the deviation of the defined route. Accuracy achieved in general (see Figure 3):

- Values are within 50cm

- 50% of the values +/- 10cm

Conclusion

In Switzerland, drones have found their place and application especially in vineyards with steep slopes, which has been greatly helped by Agroscope and the Federal Civil Aviation Authority. The homologation and testing of sprayers started in Switzerland 5 years ago, which has also resulted in many positive responses to the drones themselves. The use of drones has shown several advantages in certain cases, which is why more than 100 drones are currently flying in Switzerland.

With the use of technology comes the data, technical parameters or knowledge required to operate it.

Agriculture as such is a complex long-distance run, consisting of a number of smaller processes set up to work together to produce a final product. It is no different with the use of drones in agriculture. The actual flying and application has a lot of smaller processes behind it needed for the drone to be able to fly at all, let alone apply the necessary products to the intended location.

Flight hight vs. spray width

As you can read on the official DJI website, the most used drone in Slovakia: the DJI Agras T30 has a maximum spray width of 9 meters. However, the question remains “at what height does it have 9 meters and how does the cone change with respect to the decreasing height?”. Our company has therefore decided to obtain these data (and many others, which we will discuss below) directly from the field. Testing consisted of placing 11 posts with a 1 metre spacing between each post. Each single post had an indicator paper attached to it to ensure that we could see the accuracy of the spray. The only thing that could affect our testing was the changeable weather – especially the wind. Therefore, we ran the testing multiple times to make sure we had wind-free and accurate results. The flights were carried out with the DJI Agras T30 drone at different heights of 1, 2, 3, 4 and 5 meters above the ground. The result of the testing showed that the spray cone is variable up to a height of 4 metres above the ground (or vegetation), after a height of 4 metres the cone does not expand but then falls perpendicularly to the ground (or vegetation).

Drop size and coverage

One of the main questions about the effectiveness of drone application is the size and amount of droplets. In our experiment, we have also emphasized on solving this issue and the possibility of providing facts to customers who are interested in this issue. In the experiment with indicator papers, we examined the coverage at different application rates. The experiment was carried out at 6, 8 and 10 litres per hectare with nozzles of model XR TEEJET 11001VS The conclusion that could be drawn from repeated, multiple testing was that the drone technology can apply even at a rate of 10 l/ha more complex products, or products that require greater coverage, i.e. a greater number of droplets per cm². These additives are, for example, fungicides, which require a coverage of at least 60 droplets per cm². According to the indication papers and repeated trials, we recorded a coverage at a dose of 10 l/ha of just 60 droplets per cm², which confirms the maximum efficiency of work at doses >10 l/ha.

Swiss testing and trials

Our Swiss partners, Agroscope, have embarked on a much more detailed and extensive testing and investigation of this technology. During their activities, they have been particularly concerned with:

- Checking the spraying system before the start of the testing

- Transverse liquid application

- Influencing the application by flight height

- Calculation of the overlap of two areas

- Comparison of three methods of measuring transverse application

- Transverse application with different types of nozzles

- Measuring wind strength

- Visualizations using smoke

- Accuracy of flight paths

- Spray drift measurements

- Measuring the effectiveness of vine treatments

A more detailed description of Agroscope‘s testing can be found in the following article, Drones for spraying in Switzerland.

In 2015, a revolution in agriculture began, in which DJI drones play a significant role and are a major contributor. Drones are changing the face of global agriculture, providing enormous opportunities for precision management of agricultural inputs (fertilizers, crop protection products) and natural resources (soil, water).

With rising production costs and declining profitability, agricultural producers today should pay attention to every element of farming technology that helps reduce the cost of growing crops. The search for ways to reduce the cost of elements of agricultural technology leads us to the consideration of the widespread use of drones in the cultivation of fields in order to increase crop yields and the development of modern agricultural technologies for growing crops that conserve resources.

The drone revolution has grown globally in a relativelly short time, with drones currently being used in agriculture in many countries on different continents. The technology makes it possible to save large amounts of water ( in some cases even chemistry ), which is a big help especially in countries that have a problem with this (e.g. Spain, Italy…). We can find many articles and studies on drone solutions in agriculture, and the reasons why this technology is beneficial in today’s agriculture.

One of the interesting and informative articles is, for example, the application of fertilizers on rice, where it was possible to increase the yield by 8% with 20% less fertilizer applied thanks to a variable application with a DJI Agras T30 drone:

https://ag.dji.com/case-studies/ag-case-en-t30-jp-rice

Another article demonstrating the effectiveness and efficiency of drone technology is, for example, the application of insecticide to protect potatoes with the DJI MG-1P drone:

https://ag.dji.com/case-studies/dji-ag-case-en-sweet-potato

Improving soybean yield with spot applications for weed control:

https://ag.dji.com/case-studies/ag-case-en-t30-soybean

This article discusses an application carried out in the USA. The farm has adopted a solution for weed eradication using DJI drones and a local (or spot) application. As a result, besides saving money, it was possible to save 60% of the herbicide and also the crop, as the drone did no damage with its “ride”.

This “drone” revolution came to the Slovak market in 2019, when we entered the market as the first official service provider with Agras drones for spraying, specifically with the DJI Agras T20 model (we currently use the DJI Agras T30 model).

To date, there are various models of DJI brand spraying drones on the domestic market: the DJI Agras T30, T10, older models such as the T20 and T16. Currently the most widely used drone for spraying fields, orchards and vineyards is the DJI Agras T30, which is also currently the flagship of spraying drones.

Currently, as an official distributor of these drones, we are trying to inform the public about the use of this technology in agriculture and also about its advantages or disadvantages compared to ground-based technology.